Aaviza Electronics Pvt. Ltd

Welcome to Aaviza Electronics, a leading player in delivering manufacturing solutions across specialised wiring harness, electro-mechancial assembly, magnetic coil assembly and PCBA. Our state-of-the-art manufacturing facilities in Bengaluru and Coimbatore are dedicated to serving a diverse range of markets including Aerospace, Defence, Automotive/ EV, Consumer Electronics, Industrial, Medical, Power & Energy and Railways. Our certifications include AS9100, IATF 16949, ISO 13485, UL ZPFW2, ISO 9001.

At Aaviza Electronics, we are driven by innovation and a commitment to quality, which has positioned us to receive India SME100 award for 2 seasons in 2019 and 2023. Also, we have been recognised to be in top 10 wiring harness suppliers in India. Our expertise extends to partnering with global vendors of the Ministry of Defense, fulfilling offset obligations as per Indian defense procurement policy, and operating a dedicated Export-Oriented Unit (EOU) to facilitate direct exports and support other exporting units.

Guided by industry leaders with vast experience in the EMS sector, we focus on emerging as the One stop solution for all electronic product assembly needs. Our approach is characterized by a robust system, world-class facilities, and a continual pursuit of process innovation to support our customers with the highest quality products and services.

A Company Involved in Servicing

Our commitment to exceptional service is the cornerstone of our operations. We excel in understanding and fulfilling our clients’ needs, ensuring precision and care in every solution. As a trusted servicing partner, we dedicate ourselves to excellence, reflecting our profound commitment to client success in all we do.

Values - RECIT

- Responsibility

- Excellence

- Commitment

- Integrity

- Transparency

To become globally preferred ESDM solution provider, by adding value in each of the solutions we provide and create stakeholder delight.

Continual growth by delivering quality products and services ,

Technology enhancement to provide the best solutions to our customers

Deep rooted commitment to our planet.

Our Team

His approach is deeply anchored in ensuring customer satisfaction, a steadfast commitment to people development, and driving business growth. Under his guidance, our company has navigated the complexities of the global business landscape, consistently exceeding client and stakeholder expectations. His visionary leadership fosters a culture where innovation is at the forefront, setting high standards across all our operations.

Passionate about human resource development, he is always keen on spearheading new initiatives and fostering continuous improvement. His academic credentials include a Management Certification Course from IIM Lucknow in 2016, a Post Graduate Diploma in Marketing Management from IMT Ghaziabad (Distance Learning Program) in 2003, and a BE in Industrial Engineering from Nagpur University.

His leadership and strategic insights have been instrumental in optimizing our operational efficiencies and elevating our production capabilities to meet the highest standards of excellence. His role is not just about managing day-to-day operations, but also about driving innovation and growth, ensuring that we stay at the forefront of industry advancements.

His leadership ensures that our products and services consistently meet the highest standards of excellence, reflecting his commitment to quality in every aspect of our operations.

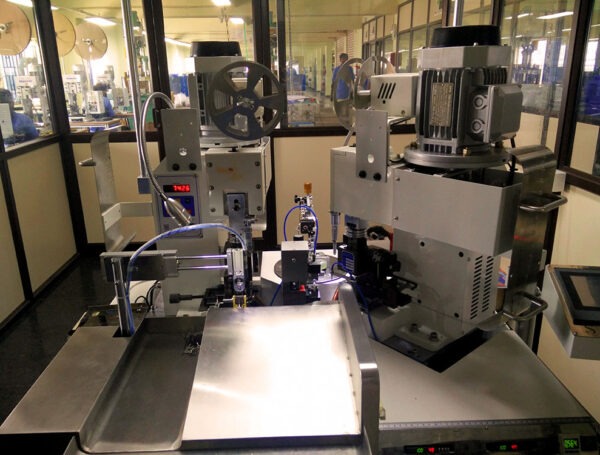

Infrastructure

Machinery

- Cut & Strip Machines

- Auto cut-strip-crimping machines

- Moulding machines

- 36 spindle braiding machine

- Potting machine

- HST conveyor

- Crimping Machine

Testing Equipment

- Push pull Guage – 1000 N

- Crimp height Micrometer

- Height Master

- Magnifiers

- Continuity, HV, IR tester

- Insulation resistance tester

- Dry Hot Chamber (00 C to 2000 C)

- Cyclic Chamber (-600 C to 2000 C)

- Humidity Chamber (95% Rh, 600 C)

- Harness cyclic bend testor

Quality Standards

Besides these quality certifications, having an in-house IPC 620 B certified trainer and workforce, we are in a better position to resolve any challenges given by our customers

Soldering: J-STD-001

IPC/WHMA-A-620B

MS75027: for dimensions without tolerance

AS9102

IS2500